Project

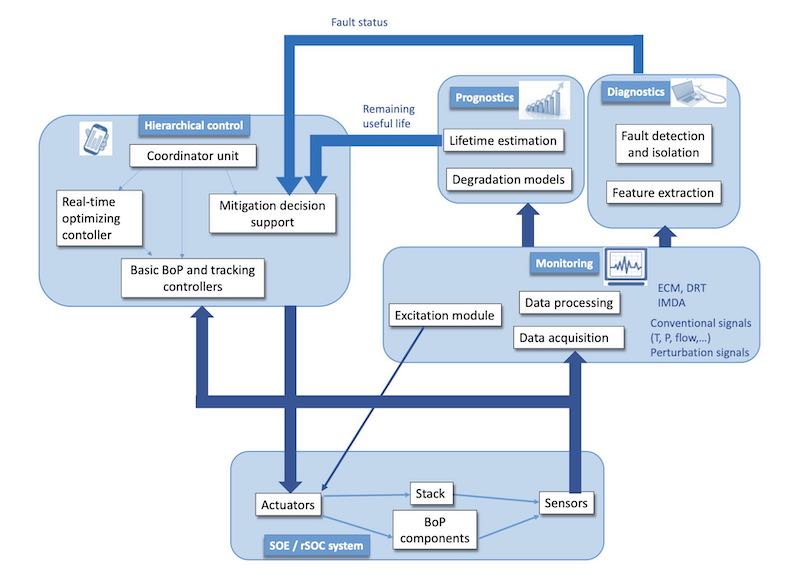

Systems deploying Solid Oxide Electrolysis (SOE) stacks or reversible Solid Oxide Cell (rSOC) stacks can play a major role in H2 production at low cost and for renewable energies storage. These operating modes with high current and transients can induce degradation that needs to be mitigated for successful system deployment. Federating the cumulated advances built up in preceding collaborative projects, REACTT, with an established expert team, will realize a Monitoring, Diagnostic, Prognostic and Control Tool (MDPC) for SOE and rSOC stacks and systems. lts hardware platform will embed diagnostics and prognostics algorithms, and interact with the system power converters without modification.

lt contains (a) an innovative excitation module to probe the stack with PRBS (pseudo-random binary signal) or sine stimuli, and (b) a control coordination unit, interfaced with real-time optimization (RTO). The latter uses on-line measurements with a constraint-adaptive algorithm that drives the system to optimal operation, respecting all safety boundaries. Together, this approach will achieve to supervise and analyze the (reversible) electrolyser system, increase its reliability and extend its stack lifetime. REACTT will demonstrate the effectiveness of this approach by tests on a SOLlDpower (SP) 5 kWe SOE system and on an rSOC x kWe CEA system, both at TRL6. This validation in two different operating modes with two different stack designs will prove the generic character of the developed tools, which can then be extended towards multiple technologies and higher power applications. lt will reduce the operation and maintenance costs by 10%; the additional cost of the MDPC tool will not exceed 3% of the overall system manufacturing costs. These ambitious targets will be pursued in close collaboration between 6 R&D (lJS, UNlSA, CEA, VTT, EPFL, ENEA and HES-SO) and 3 industry partners (SP, Bitron and AVL) on the whole value chain from tests to systems through hardware and software developments.

THE CONCEPT OF REACTT